Also, if you look at them closely, you may see big dark specks in the filament, though it depends on the filament brand.Īs such, you need to use a 3D printer with a big nozzle that will accommodate the large specks. Many wood filament looks similar to the medium density fiberboard. Therefore, 3D wood printing needs you to exercise patience, and you will need advanced 3D printing skills to do it.

Cetus3d wood filament how to#

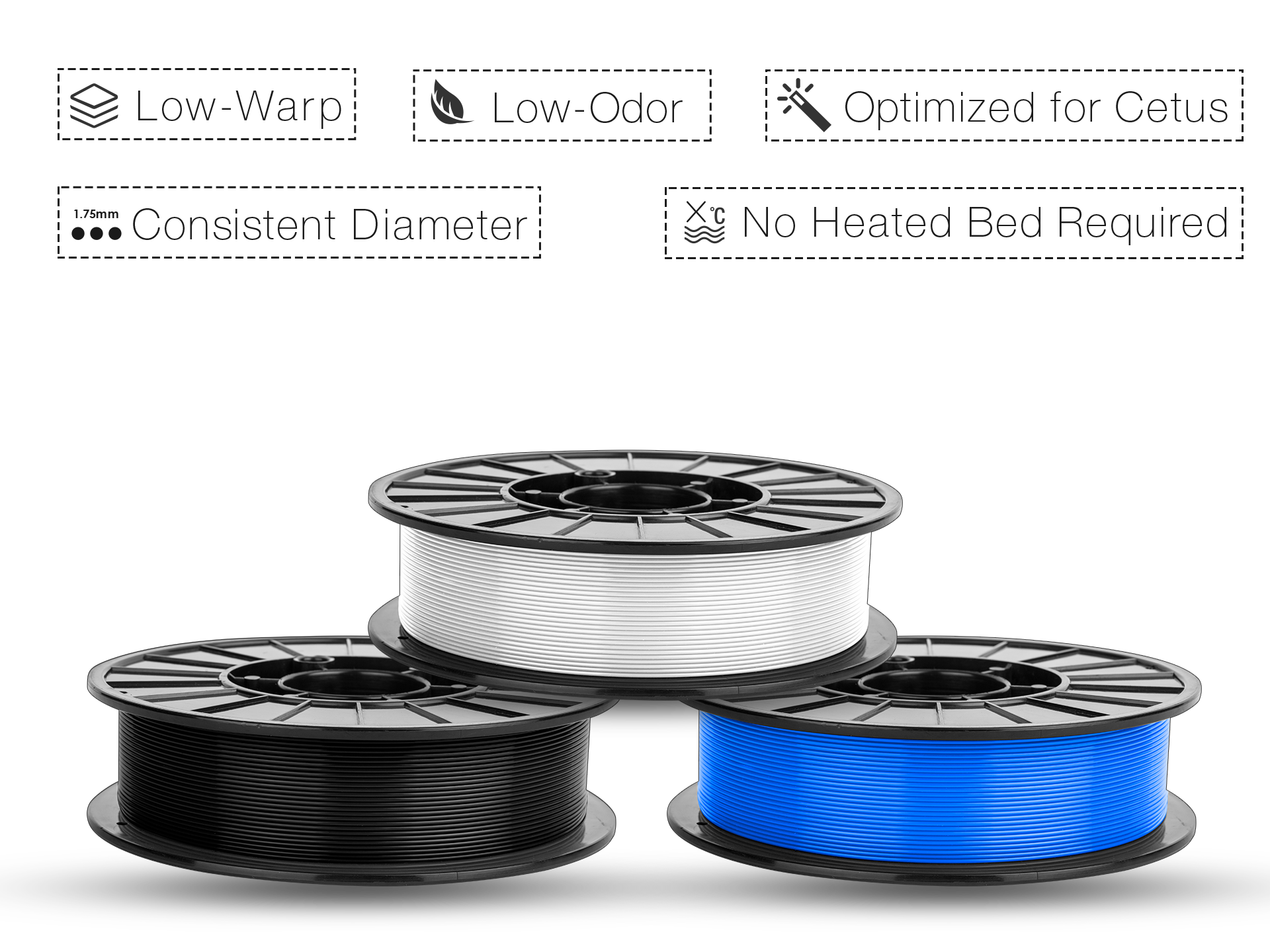

How to Print Wood Filament?ģD wood filament printing may not be as simple as using a 3D printer to print other common filament types. Then, the laser beams add extra energy to melt the powder for a solid object.Īfter finishing your print process, you end up with a big block of warm powder that hosts the 3D model inside it. After the printer prints a layer, the roller spreads over a new layer of powder on the bed.įurthermore, the printer contains a chamber that heats the powder below its melting point. The technology helps you print the model layer by layer using a laser that draws lines on your3D printer powder bed.Īdditionally, the powder bed melts, bonding the powder with solidified layers as they were printed earlier. If you want to print 3D wood designs, you need to use laser sintering technology. The likes of architectural scale models, figurines, and awards fall in this category.ģD printing with wood enables you to create a model that cannot be manufactured using traditional woodworking techniques. Most of the models you put on your desk and shelf are made of wood. Also, the model surface, which remains porous, has a sandy, grainy look.Īdditionally, wood remains a perfect material for complex models as it allows for 3D printing of interlocking and moving parts. Wood models are made from a brown, granular powder extracted from chips of wood. Print temperature: Hot end 210-230 degrees celsius, heated bed temperature 0-60 degrees celsius Can You 3D Print Wood?.Filament spool:250 grams, 500 grams, and 2.3 Kg.The wood type used: Pine, Olive, Cedar, Willows, Ebony.Its range of wood filaments, called Easy Wood, comes in seven different colors. Print temperature: hot end 200-230 degrees celsius and heated bed temperature of 0-60 degrees celsiusĪ Dutch filament manufacturer produces this wood filament.Filament composition: 40% wood and 60% PLA filament.So, it means the filament provides a pleasant printing experience. They offer rave reviews, terming it as a filament that prints like butter. CorkFill hot end temperatures are 210-230 degrees celsius and a heated bed temperature of 0-60 degrees CelsiusģD printing enthusiasts like the functionality of the Filamentive Wood Filament.Print temperature: WoodFill hot end 195-200 degrees celsius and heated bed temperature 0-60 degrees Celsius.Filament spool sizes: WoodFill, 600g, 1.8kg, and Corkfill 650g.

If you want to post-process your print with CorkFill or WoodFill, you can easily sand them up for better print quality.

The Dutch company ColorFabb manufactures woodFill and CorkFill brands it’s a premium filament, quite expensive in the market but boasts an attractive surface look.Īlso, it remains a composite filament that combines PLA filament and wood fiber.Īdditionally, the filament produces a sweet aroma and is easy to print. The filament manufacturers take advantage of the soft nature of the wood particle to make filament that looks like wood due to the color. Interestingly, some manufacturers design wood-like filaments that don’t have any wood particles but only have wood colors. The wood filaments lack the abrasiveness of other types of composite filaments like carbon fiber or metal-filled filaments. Therefore, they form filaments whose final 3D object contains properties that make them look like wood.Īlso, the wood-filled filaments consist of 30% wood fiber, although the exact number will vary based on filament type. Wood filaments remain composites that combine the base filament like PLA and real wood fibers. You need to mix wood with PLA before you apply it in the 3D printing process. Thus, wood cannot be used for 3D printing on its own. Real wood refers to pure wood in its element. The article provides information about 3D printing with wood that will help you use wood-filled filament if it best suits your 3D printing needs.

If you 3D print using wood filament, the final print will look and feel like wood.ģD printing with filament keeps gaining traction, and its application can be seen in household decorations, cosplay props, and toys.

0 kommentar(er)

0 kommentar(er)